Lopburi, seed conditioning plant

The history and background of Lopburi, seed conditioning plant

CHAROEN POKPHAND PRODUCE CO., LTD. operates the seed conditioning factory in Lopburi as a part of Crop Integration Business under Charoen Pokphand Group. The company specializes in seed conditioning of hybrid corn seed that adheres to international standards and contributes sustainable benefits to the agricultural community. The factory has been in operation since 1979. The company is dedicated to continuously developing seed production to meet customer needs while aligning operations with the organization’s values. It emphasizes creating benefits for all three parties: the country, the group, and the public. The seed conditioning factory receives high-quality corn seed raw materials from promoted sources undergoes modern and traceable production processes and produces standardized quality products for export to markets including Thailand, Laos, Cambodia, Myanmar, Vietnam, and other countries in Southeast Asia. Furthermore, the company also emphasizes the importance of conducting business with a continuous commitment to being environmentally friendly. This commitment is evident from the conceptualization to the installation phase which focuses on social and community responsibility to benefit country, society, and organization. This approach ensures the business’s sustainable and continuous operation while positively impacting the environment

Vision

Become a leader in seed quality field

Mission

- Prioritize product quality to ensure efficient and effective production control with focus on safety, occupational health, environmental conditions, and social responsibility. Develop personnel, production technology, and foster continuous innovation and manage energy appropriately by utilizing resources efficiently.

Our 2 seed processing plants:

- Seed Processing Plant Soi.19 located at 187 Moo.13, Phatthana Nikhom, Phatthana Nikhom, Lopburi

- Seed Processing Plant Soi.12 located at 21/1 Moo.4, Dilang, Phatthana Nikhom, Lopburi

- 1979, Plant 1 was established and corn seed production operations were carried out under the name of Bangkok Seed Industry Co., Ltd.

- 1980, Start produced corn seeds Suwan 1 variety which commenced for distribution to farmers.

- 1981, Start produced corn seeds, CP 1 hybrid variety and started distribution to farmers.

- 1992, Start produce corn seeds, CP 888 hybrid variety and distribution to farmers.

- 1996, Plant 2 was established under the name of Bangkok Seed Industry Co., Ltd.

- 2011, the company changed its name from Bangkok Seed Industry Co., Ltd. to Charoen Pokphand Produce Co., Ltd.

Factory Potential & Standard Systems Information

Seed Conditioning Plant Capacity

- Corn seed production capacity of 10,000 tons per year per plant (total capacity of 20,000 tons per year)

- Production and distribution of corn seeds under brands Dok Bua, Bai Pho, and Chang Daeng

- Products are categorized into 3 types: maize, baby corn, and sweet corn.

Organization Standard

- ISO 9001:2015

- ISO 14001:2015

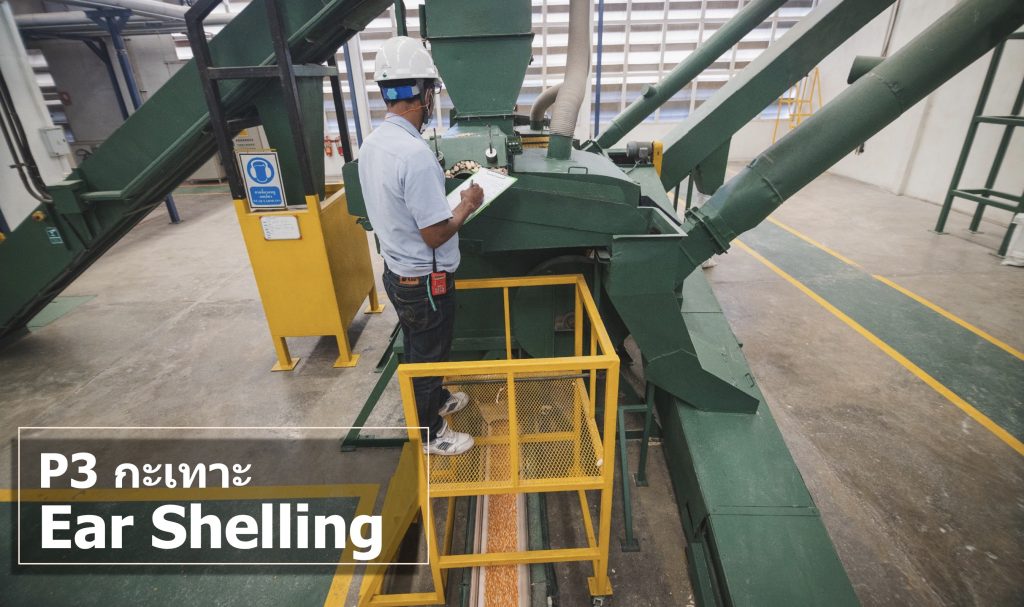

Steps and manufacturing processes are divided into 9 steps as follow:

- Ear Sorting

- Ear Drying

- Ear Shelling

- Seed Drying

- Air Screen Cleaning

- Seed Sizing

- Gravity Separator

- Seed Treatment

- Packing

Raw Material and Product Storage

The seed conditioning plant is dedicated to delivering standardized quality corn seeds to emphasize the importance of preserving the quality of raw materials and corn seeds. This is achieved through the use of a Cold Room equipped with temperature and humidity control to ensure suitable conditions for quality of corn seeds.