Kumphran Organic Fertilizer Plant

Kumphran Organic Fertilizer Factory's Background and History:

- 1991: The composting and production of organic fertilizer commenced to be utilized in farm operations and promotional activities. The product type is granular.

- 1997 – 2005: Development in product production for commercial sales including both granular and powdered fertilizer.

- 2011 – 2012: Research on the fermentation process of fertilizer using technology from various countries such as China, Japan, and Germany, to be adapted in the fermentation process of the fertilizer.

- 2013 : The construction project of the manufacturing plant in Khampran, Amphoe Wang Muang, Saraburi was initiated. The plant produces organic fertilizer in granular and powdered as well as soil and plant beneficial microorganisms.

- 2014 to present: The production of organic fertilizer for sale under the brands “CP Mordin” and “Farm Pro” began.

Factory Potential and Quality Standard Systems Information:

- Production Capacity of the Organic Fertilizer Factory in 2023:

Granular Type: 24,000 tons

Powder Type: 7,500 tons

Total: 31,500 tons

Various Quality Standards:

- ISO 9001:2015 TH16/9821 SGS since December 8, 2016

- Organic Thailand Standard since December 22, 2018 for both powdered and granular in organic fertilizers certified by the Department of Agriculture, Ministry of Agriculture and Cooperatives.

- IFOAM Standard since July 19, 2022 by ACT Organic Company Limited Certificate No. 65-137

- Campaign Activity to Reduce Occupational Accidents to Zero in 2022 by Thailand Institute of Occupational Safety and Health (Public Organization) or “TOSH”

- Outstanding Safety Award from the Safety Promotion and Compensation Fund (SPCF) in the areas of safety, occupational health, and environmental conditions at the national level at the Diamond Level (7th year) in 2022

Organic Fertilizer Manufacturing Plant:

- Raw Material Fermentation Section

1.1 Composting Area

1.2 Fertilizer Pile reverse Vehicles

2. Production/Warehouse Section

2.1 Fertilizer Pelletizing Machine

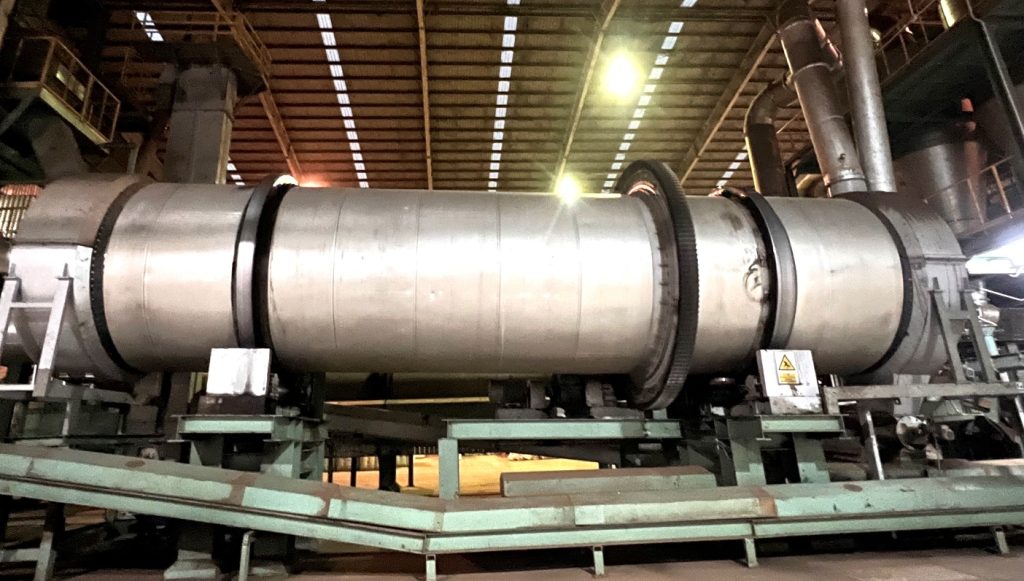

2.2 Raw Material Drying Tubes/Product Drying Tubes

2.3 Packaging Line

2.4 Overall Environmental

โรงงานผลิตปุ๋ยอินทรีย์

1. งานหมักวัตถุดิบ

1.1 ลานหมักปุ๋ย

1.2 รถกลับกองปุ๋ย

2. งานผลิต/งานคลัง

2.1 เครื่องอัดเม็ดปุ๋ย

2.2 ท่ออบวัตถุดิบ/ท่ออบสินค้า

2.3 ไลน์บรรจุสินค้า

2.4 และสภาพแวดล้อมโดยรวม