Vietnam, seed conditioning plant

Background of Vietnam, seed conditioning plant

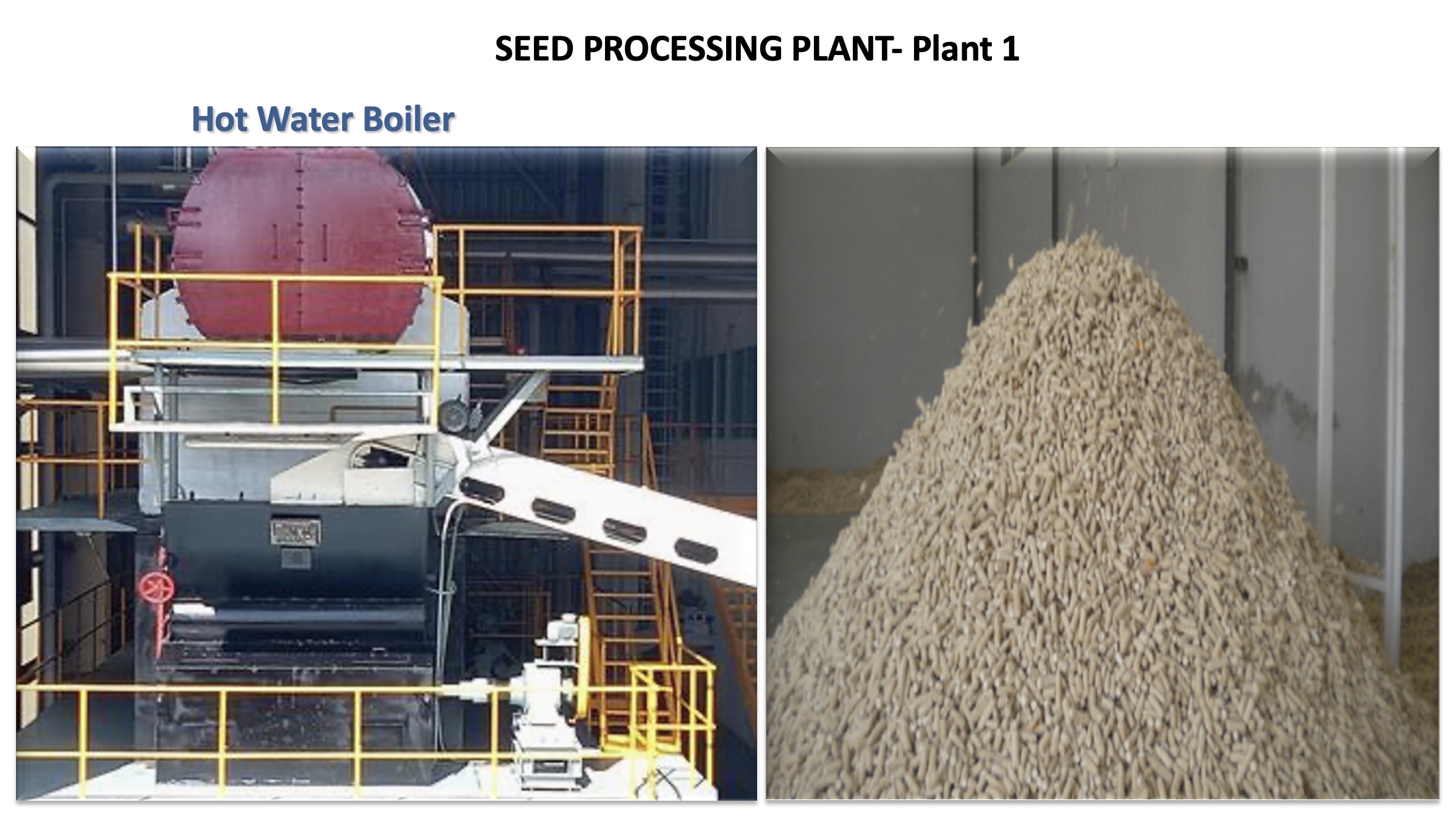

Seed processing in Vietnam was established in 1998. It can produce 10,000 tons of seeds per year and equipped with a cold storage room for product preservation.

ห้องปฏิบัติการเมล็ดพันธุ์

Seed Laboratory

The Seed Quality Assurance Center was established in 2000 and located at C.P. Seeds Vietnam Co., Ltd., Dinh Quan, Dong Nai.

Purpose of Seed Quality Testing Laboratory:

- To control the quality of raw material inspection process, Factory 1

- To control the quality in the seed conditioning process (drying, dehusking, moisture reduction, weighing, chemical treatment, and packaging)

- To control and ensure the quality before distribution

- Handling Complaints about seed quality

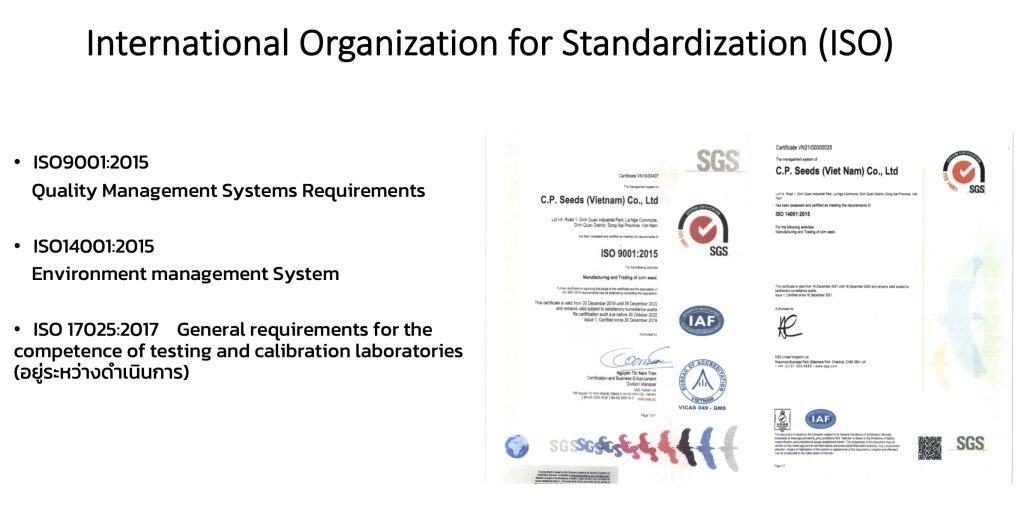

Standards:

- International Seed Testing Association (ISTA)

- ISO 9001 Quality Management System standards

- ISO 17025 Laboratory Competence Certification standards

- Vietnam’s Ministry of Agriculture and Rural Development QCVN 01-53:2011/BNNPTNT standards

Testing Procedures:

- Random sampling for each step and LOT

- Moisture content verification using calibrated instruments with the HOT AIR OVEN standard method

- Germination testing through paper-based

- Hardness testing through paper-based

- Purity testing through Strip test and Elisa

Other Supportive Activities:

- Certification application processes

- Inspection of packaging and products

- Laboratory testing for seeds, chemicals, and seed coating color